| Model |

BS 170 FH |

| Motor power, W |

900(230V)

900/550(380V) - optional |

| Saw blade dimensions, mm |

2110 x 20 x 0.9 |

| Cutting speed, m/min |

80 (230 V)

97 (110V)

80 / 40 (380 V)

|

| Angle of rotation of the saw frame, ° |

0 ~ 45 (60) |

| Section of workpiece at – 90°, mm |

●170

■ 140 x 140

▅ 210 x 140 |

| Section of workpiece at -45°, mm |

● 120mm

■ 110 x 110mm

▅ 130 x 110mm |

| Section of workpiece at -60° |

● 70mm

■ 60 x 60mm

▅ 170 x 60mm |

| Table height, mm |

970 |

| Power of coolant pump, W |

150 |

| Dimensions: |

| Length, mm |

1260 |

| Width, mm |

540 |

| Height, mm |

900 |

| Weight (net), kg |

160 |

| Weight (gross), kg |

200 |

Warranty - 1 year.

PURPOSE:

The band saw MetalTec BS 170 FHE is designed for cutting workpieces from metals: non-ferrous, nickel, titanium, as well as high-alloy and structural steels.

The design of the machine is classic for this type of equipment: a massive bed is used as a base, and a saw frame is used as a cutting module. The cutting process itself is carried out by a saw blade (band saw), which is welded into a ring and mounted on a saw frame, by pulling on pulleys. The saw frame lowers under its own weight, and the adjustable hydraulic cylinder (hydraulic unloading) allows you to adjust the speed of lowering the saw frame, depending on the installed workpiece and sawing modes.

The advantages of manual metal band saws:

- High machining accuracy due to guided guides with bearings - allows you to get a better cut compared to analogues from other manufacturers.

- Saving material during processing, due to the small cutting width - allows you to save material, as well as produce accurate cuts due to minimal vibration of the band.

- The ability to cut at different angles - up to 45 (60) ° - allows you to cut at different angles, for subsequent welding of structures.

- Batch cutting, and cutting several workpieces at the same time - allows you to save processing time by sawing several workpieces in one setting.

- The ability to cut various workpieces: pipes, profiles, etc. - makes the machine widely applicable both in small industries and workshops, as well as to mass-produce most of the materials used in production.

PROCESSING SCHEME:

| STEEL PIPES |

METAL PROFILE |

METAL BAR |

|

|

|

DESIGN FEATURES:

|

POWERFUL ENGINE

Reliable operation throughout the entire service life. Drives the band saw blade to provide optimum cutting speed for various materials.

|

|

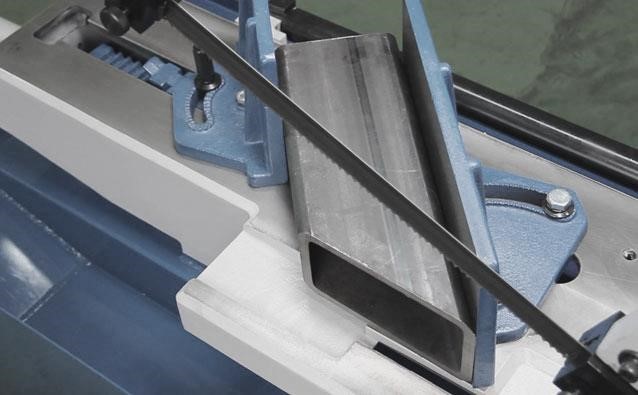

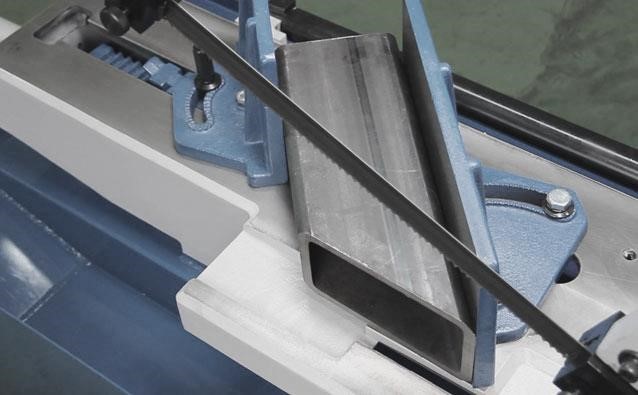

RELIABLE MECHANICAL VICE

Provides reliable fixation of the workpiece due to the large surface area of the corrugated jaws. The vise is set in motion by a convenient flywheel, which makes the fixing process fast and protects against arbitrary displacement of the workpiece.

|

|

TURNING SAW FRAME

The solid saw frame made of gray cast iron provides structural rigidity and dampens vibrations that occur during operation.

The ability to rotate the saw frame makes working on the machine more convenient, saves space in the workshop.

|

|

HARD AND HEAVY BED

The design of the machine is a reliable and rigid base (bed) on which a durable saw frame made of cast iron with a gear drive and a band saw blade is installed.

|

|

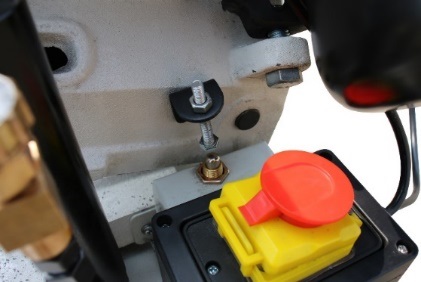

CUTTING EMERGENCY STOP SYSTEM

Emergency stop button for band saw movement to prevent accidents while operating the machine.

|

|

TWO POINT AUTO COOLANT

To remove chips from the cutting zone, to prevent overheating of the cutting edge of the tool and the workpiece, Metaltec machines are equipped with an automatic (multi-point) coolant supply system (coolant).

|

|

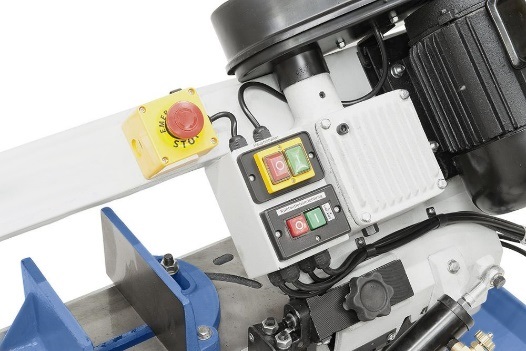

MODE SETUP

The ability to choose the optimal speed of the band saw blade for processing workpieces from various steel grades.

|

|

HYDRAULIC UNLOADING SYSTEM

The lowering of the saw frame into the cutting zone of the workpiece occurs due to the own weight of the saw module, where the lowering speed is controlled by a hydraulic cylinder (hydraulic unloading). |

|

CONTROL PANEL

The machine control buttons are located on the front side of the saw module, which makes working on the machine convenient and safe. |